UK: Testing is underway with what is thought to be the first installation of European Train Control System equipment on an operational steam locomotive, as part of a plan to secure the long-term future of heritage traction operation on the national rail network.

The £9m ‘pathfinder’ project is being undertaken as part of the £1·4bn East Coast Digital Programme, which will see ETCS Level 2 installed on the southern section of the East Coast Main Line between Grantham and London King’s Cross. It aims to determine whether it will be technically and commercially viable to continue the operation of heritage steam and diesel locomotives on routes where ERTMS and cab signalling have replaced traditional lineside equipment; Network Rail estimates that heritage rail operations are worth more than £600m/year to the UK tourist economy.

The project is being undertaken though a collaboration between Hitachi Rail (onboard equipment), engineering firm AtkinsRéalis (fitment design), the A1 Steam Locomotive Trust (loco owner) and infrastructure manager Network Rail (integration).

Ed Akers, Industry Partnership Director, ECDP at Network Rail, says the technically challenging work was being undertaken through a ‘creative solutions-based’ mindset, ’free of the shackles of a restrictive transactional approach’.

Bringing old and new together

Class A1 steam locomotive 60163 ‘Tornado’ was selected for the trial as it was newly-built in 2008, so a full set of drawings was available. The loco already has a full electrical power system, although the ETCS equipment consumes more power than all of its existing electrical systems.

‘We are very pleased that ‘Tornado’ was selected as the world’s first operational steam locomotive be fitted with ETCS’, said Rob Morland, electrical engineer at The A1 Steam Locomotive Trust. ‘We have extended ‘Tornado’’s already comprehensive electrical system to provide the additional power required. This has included the fitment of a second steam turbogenerator [manufactured by DB Meiningen], a new axle driven alternator [designed and built by the A1 Trust] and a third battery bank, dedicated to ETCS. The system is designed to provide a very reliable electrical supply’.

Morland said the cab of a steam locomotive was ‘a very challenging environment. It has got heat and cold. It has got coal dust, which when wet is a very good electrical conductor. It has got water, it has got shock and vibration which all contribute to stress any installation.’

He said the best advice for any electrical system on a steam locomotive was to ‘build it as strong as you possibly can, and it might survive’.

The work drew on experience with fitting the TPWS train protection system, on-train monitoring recorders and GSM-R radios to heritage traction.

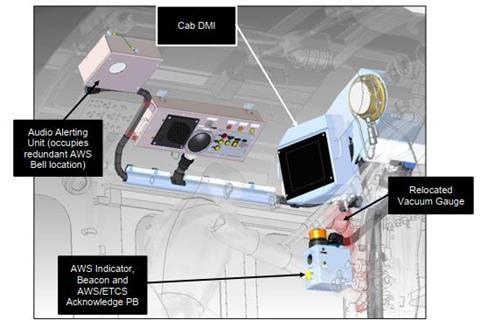

Amy Clauston, Human Factors specialist at AtkinsRéalis, said ‘our challenge was to integrate the latest in digital signalling to this steam locomotive environment that was never designed with ETCS in mind. So we are bringing old and new engineering together.’

The need to support tender first-running requires two ETCS screens in the cab rather than the usual one. A particular challenge comes from the changing light intensity in the open-backed cab, as the screens must be readable at different times of day, in tunnels and when the firebox door is open.

Touch screens were tested to assess the impact of vibration, dust, water, weather, and ‘drivers’ grubby fingers’, while noise measurements were taken across several types of heritage locos on various routes to ensure the alerts would be audible.

Keeping the electrical equipment cool in the hot environment required sealed enclosures to keep coal dust out, combined with cooling fans in the water tank to take heat away.

AtkinsRéalis has worked on many retrofit projects, but Clauston said ‘the challenge here was to very much respect the heritage aesthetics of the locomotive, and so equipment that could be hidden or disguised to appear in keeping was’. The DMI screens are designed to be removable when the loco is running on a route without ETCS.

Hitachi Rail UK Vice-President Andy Bell said the retrofit was ‘a world first that has tested our technology in one of the most complex operating environments’. The ‘very special project’ had demonstrated ‘not only the adaptability of Hitachi Rail’s system but also what’s possible when we respect the past while designing for what’s next, combining engineering expertise with deep, trusted partnerships across the industry’.

The project was aligned with a scheduled overhaul of the locomotive, but the co-dependencies between the two projects meant the work took longer than anticipated. This experience will inform the planning and scheduling of future first-in-class fitments.

The complete design has already been shared for use on other steam locomotives. ‘The lessons we’ve learned here have created a valuable blueprint for future projects’, said Bell. ‘Carrying forward the relationships, insights and technical progress from this work will be essential to maintaining momentum, not only for heritage integrations but for wider applications across modern rolling stock as well.’

Akers said ‘the innovation and expertise delivered through the pathfinder has provided significant learnings for our programme, applicable for fitment across a range of fleets’, although the retrofitting heritage traction will not become the production line process that has been achieved on more modern and standardised fleets.

Dynamic testing

Initial testing with ‘Tornado’ took place at the heritage Great Central Railway with towed movements over balises.

Dynamic testing is being undertaken overnight during April between Shrewsbury and Newtown on the Cambrian lines, where Network Rail’s ETCS Level 2 Early Deployment Scheme went live from 2010. Earlier proposals to equip steam locomotives for use on this route did not lead to any practical development.

The test trains are being operated by heritage and charter operator West Coast Railway, with commuter operator Govia Thameslink Railway providing ETCS testing expertise. ‘This has been both a thrilling experience and a real privilege to support the wider industry in the deployment of ETCS’, said Matthew Teller, Head of Systems Integration for ERTMS at GTR. ‘Having introduced digital signalling on commuter services in London, Govia Thameslink Railway has become an experienced industry leader in ETCS testing, so we’re delighted to be able to collaborate.’

Further trials are to be undertaken later this year with Class 55 Deltic heritage diesel locomotive ‘Royal Scots Grey’ dating from 1962. Plans to equip a ‘Black 5’ steam locomotive for further testing have been dropped. Further refining and assurance will be required ahead of any main line use of heritage traction under ETCS Level 2.

‘Steam locomotives are more than just machines, they’re living, breathing monuments to British innovation’, commented Alejandro Moreno, Market Director Rail & Transit UK & Ireland at AtkinsRéalis. ‘We had to find creative solutions to integrate modern technology in an environment which is noisy, dusty, hot and exposed – all the while preserving ‘Tornado’’s authentic character and enabling operation on the digital railway.’