UK: Infrastructure manager Network Rail is trialling a passive heat exchanger developed by Flint Engineering which can lower the temperature in signalling equipment cabinets, reducing the risk of failures during increasingly frequent hot weather events without requiring power, maintenance or internal modifications.

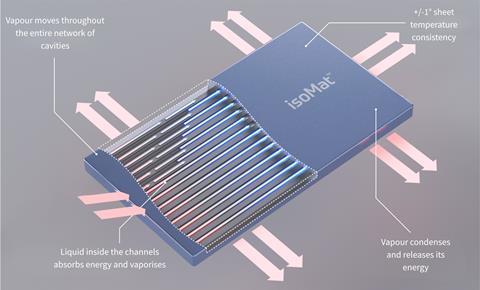

IsoMat is based on flat aluminium sheets with an internal network of sealed channels. When exposed to extreme temperatures, the liquid within these channels undergoes a rapid cycle of evaporation and condensation, resulting in near-instantaneous heat transfer. IsoMat can be can be installed by two people in under an hour, with no modification to the cabinet itself, no moving parts and no maintenance requirements

It can provide temperature reductions of over 21% on the hottest days, when signalling cabinets can otherwise exceed 70°C.

Initial trials are underway at 10 of the highest-risk cabinet locations the Tonbridge to Hastings line, and further installations are planned for next year. Future large-scale deployments would be subject to Network Rail’s standard procurement and evaluation processes to ensure open competition. Flint Engineering also reports interest from North American and the Middle East.

The trial forms part of Network Rail’s wider exploration of ways to combat the effects of climate change. ‘Flint’s IsoMat technology provides a simple, effective solution to a complex problem, helping us maintain service reliability even during heatwaves without requiring power, maintenance or complicated installation procedures’, said David Davidson, Chief Operating Officer for the South Eastern Railway partnership of Network Rail and train operator Southeastern.