GERMANY: DB Cargo is to invest in a fleet of purpose-built flat wagons and swap bodies to supply raw materials for the ArcelorMittal steel plant in Eisenhüttenstadt under a 10-year logistics contract running from mid-2021 to 2031.

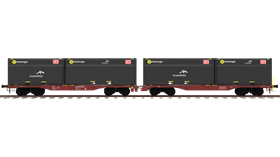

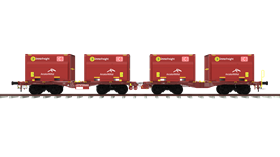

Announced on November 16, the contract covers the movement of up to 4·2 million tonnes of iron ore, coke and limestone per year to one of Germany’s largest steel production facilities. The raw materials will be carried in 1 408 containers which will be transported on 352 multi-functional twin wagons to be procured by the operator.

The wagon concept has been developed by DB Cargo’s logistics partner Innofreight, with a view to optimising the load volume for each of the raw materials. Innofreight will also build and operate two semi-automated loading and unloading facilities at the Eisenhüttenstadt plant.

The use of purpose-built containers optimised for the different properties of ore, coke and limestone is expected to increase the payload of each train by around 20%, cutting the overall number of trains operated. Automated loading and unloading of the flatbed block trains at the terminals will eliminate much of the shunting currently required, while reducing the amount of dust and noise created.

‘ArcelorMittal Eisenhüttenstadt is implementing one of the most state-of-the-art raw materials logistics systems in Europe’, said the steel group’s Lead Buyer for Rail Sybille Klipstein. ‘We’re setting new standards in efficiency, environmental protection and occupational safety.’

‘We have been supplying ArcelorMittal with raw materials for years and transporting finished steel to customers, in particular in the automotive industry and plant engineering’, said DB Cargo Management Board Member for Sales Pierre Timmermans. ‘Now we are investing a considerable sum in this long-standing partnership. Our new wagons for ArcelorMittal will have a durable underframe, while the removable superstructure is designed to be flexible so that it can be replaced more frequently. We will also be able to customise the superstructure as the requirements change.’