Efficient shunting requires precise control of speed and routes. With YardLynx, we deliver a proven real-time control system for variable route, retarder and conveyor control in hump yards.

As an experienced provider of railway control systems, we at Kontron AIS develop and deliver software-based solutions for safe and efficient shunting operations in hump yards. With more than 30 years of experience in retarder control for train formation systems, we combine deep railway domain knowledge with modern control technology to support freight and infrastructure operators in managing complex yard processes reliably.

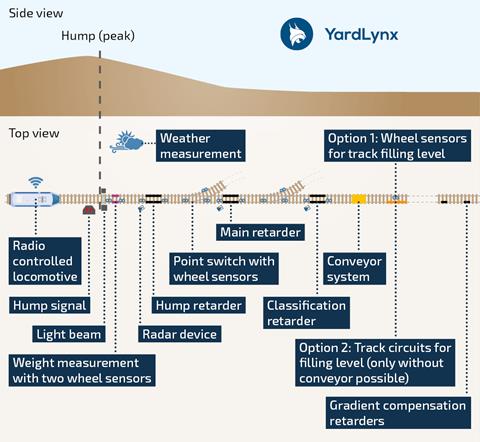

YardLynx is our variable route and retarder control system for hump yards. The real-time system controls the route and speed of each individual freight wagon from the hump to the classification tracks, ensuring ready for coupling target braking. This enables high throughput rates, stable shunting quality and gentle handling of wagons, even under changing operational and weather conditions.

The modular architecture of YardLynx allows flexible adaptation to different yard sizes, performance requirements and topologies. The system supports various retarder configurations, including hill retarders, main retarders, classification track retarders and gradient compensation retarders, as well as hydraulic, pneumatic and electrodynamic retarders. Optional functions include fully automatic route control and the integration of conveying systems to increase yard performance.

YardLynx provides comprehensive monitoring, diagnostics and data logging functions. Real-time calculation of speeds and distances, extended collision protection and the detection of potentially critical situations contribute to safe and efficient operations. Integrated weather management, based on meteorological sensors and weather models, supports reliable braking performance under varying environmental conditions.

We support our customers throughout the entire lifecycle of the system. Our services range from preventive and predictive maintenance to the replacement of individual components and complete control platform retrofits during ongoing operation. Remote access and integrated maintenance functions enable early detection of maintenance needs and help maximize system availability.

YardLynx is designed and approved in accordance with SIL 2 safety requirements and has been proven in operation for more than 30 years. We are a long-standing, prequalified supplier to Deutsche Bahn AG in the field of retarder and conveyor system control, with multiple successfully implemented projects.

Solutions

- Variable route and retarder control for hump yards

- Real-time control of freight wagon speed, distance and routing

- Support for hydraulic, pneumatic and electrodynamic retarders

- Optional automatic route control

- Collision protection

- Monitoring, diagnostics and predictive maintenance

- Retrofit solutions and lifecycle support

- SIL 2 compliant system according to DIN EN 50716 (CENELEC)