Digitalization and harnessing the power of The Cloud were at the front of discussions during the Siemens Mobility ‘Industry Trends’ event, delivered live online in October.

Launching the event Siemens Mobility CEO Michael Peter explained how digitalisation can make a huge difference in achieving the shared goal of having climate neutral transportation by 2050. He highlighted three areas where Siemens Mobility is working to move this journey forward: making trains more attractive places to be for passenger whilst becoming more energy efficient and offering a better ride; improving the capacity of networks through Cloud-based interlockings and ETCS with driverless operation and the support of artificial intelligence to ensure trains never fail and improving the utilisation of trains, which were only seeing average loadings of between 55% and 70% pre-Covid, through new solutions that will make booking and travelling easier – ensuring that the remaining 40% of capacity is better used.

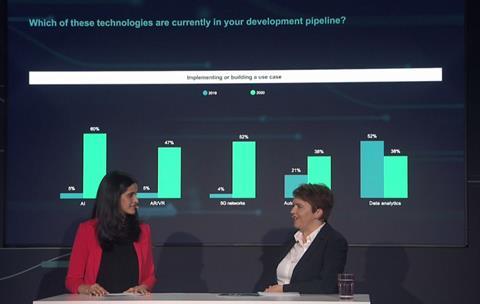

To focus on digitalization has been supported by a study Siemens Mobility recently conducted, where they asked over 100 global executives about which digital technologies have the greatest potential to improve the transportation sector in the next five years. Devina Pasta, Head of Digital, Technology and Strategy at Siemens Mobility, further explained the study results: “AI and data analytics for data-driven decision making will remain important aspects in modernizing transportation, but there are additional technologies coming to the fore such as “5G,” “AR/VR” and “autonomous technology,” which will increase the use of ATO, as well as support efforts to provide greater reliability, sustainability, and increased capacity and utilization in trains.” She also explained that the industry is moving from pilots to seeing tangible benefits of these solutions. For example, through AI driven algorithms, the failure of a component can be predicted, before it fails, thus reducing unplanned downtime.

Smart Trains

Starting with the trains themselves Gerhard Paal, Siemens Mobility Head of Sales for Digital Services, Customer Services, explained that whilst the talk has been of ‘intelligent trains’ the more correct explanation is that trains now form part of an intelligent, smart system where the data transmitted in real time from sensors on a train is processed in The Cloud, using analytics and algorithms, to create information that has a value to operators. Paal noted “Components are producing its diagnostic messages; continuous sensor readings, maybe every 200 milliseconds, is what you’re looking for because that describes each and every movement or acceleration of a component.” With such a busy pipeline of information decisions need to be made about how this is processed so that only time critical data is used to create alerts about a possible component failure or the need for repair within hours, less critical work is scheduled as part of the routine maintenance programme and the long term condition of components is monitored. Rules can also be set to enable data to be collected or relayed once certain thresholds are reached or exceeded, again triggering a response. With data relatively cheap to store it is also retained for future interrogation should a trend of concern be detected or if components prove to have longer operational lives than forecast and costly maintenance or replacement can be reduced. “Data is never lost, so you can always go back and revisit it.” Paal added.

The link between trains and infrastructure is also underlined by this improved smart system; feedback from bogies not only covers motors and wheel bearings but the quality of the track, where real time data can be compared with past measurements to generate alerts about any degradation in ride quality.

For Siemens Mobility the target is to see train reliability close to or even at 100%, Paal provided further detail about how this can be achieved “A train will probably have a small number of mobility critical components; if they fail then you can’t provide the service. You really want to own and understand them, and therefore condition monitoring of those components is important; this is probably the most important aspect. If you can acquire data from a mobility graded component you don’t just understand its condition, you can also create a trend that plots when you would need to initiate maintenance activity. A whole train will provide something like two and a half to three thousand diagnostic messages every day; that information allows you to understand the health status of the train which, in turn, gives you a lot of power, a lot of understanding for your maintenance process. If you know what you have to focus on then you can make sure that this is part of the overnight work that means the train will run the next day throughout each peak hour.”

This data is further enhanced when linked to the Automatic Vehicle Inspection system that can check a number of vital components as a train passes though it on a depot, assessing wheel profiles and wear, the condition of brake pads, and other bogies components. Again this not only creates alerts if a tolerance is exceeded but maps out when future maintenance such as reprofiling of wheels will be needed and enabling train planners to get the optimum use of a component by adjusting train diagrams appropriately. Paal explained “Remember on some of the older fleets some operators are still measuring this by hand; it really takes a long time to get all the data, it takes hours. With AVI you get it automatically and the algorithms look for trends and certain matches before providing your maintenance schedule automatically. I think that is clearly a big time improvement.”

Of course the ability to identify components which are performing better than their original design specification also has significant financial implications; Paal gave one example “The most expensive part on a train to maintain is a bogie, because you have to remove it completely. Typically a bogie might have an operational life between an overhaul of around eight years. If you are able to stretch the lifetime of a bogie to 10 years, you’d save a lot of money over the whole life time.” With dedicated sensors on a bogie the stretching of maintenance periods can be managed whilst maintaining the condition of the train and the business case for investment in remote monitoring is justified by the significant reduction in the total cost of ownership.

This is all managed by Siemens’ Railigent system which makes intelligent use of rail data and generates the valuable information that enables customers to get more out of their systems; trains and infrastructure.

Not only does Railigent provide a platform which covers the whole value chain from capturing data in an intrusion-free way to its transmission and analysis but it is an open ecosystem that is opened up to third parties; a customer which already has digital services can integrate their application with Siemens’ systems and either use the data on their own platform or share space with Siemens. Paal explained “We can use Railigent to work together with a partner; many of them don’t have their own platform, but they have data, whilst large customers might have a platform but we still work with them. The key thing is you need to have an open architecture or an open platform that allows you to exchange data and also allows a partner or a customer to come join you and this is what we do. I think those two aspects that we provide is what makes Railigent unique.” One final aspect is the ability to focus on where improvements can be made to the life cycle of components, a specific item which needs replacing more frequently than other parts can be identified and Siemens or its supply chain can share data and address this as the next generation of components is designed, further reducing cost and improving overall reliability and train availability.

As Devina added: “All the benefits that you have heard so far show that through the digital asset management solutions we can help our customers achieve the optimum balance of performance, costs and risk, to also ensure profitability and competitiveness for our customers.

Intelligent Rail Infrastructure

With infrastructure forming another part of the intelligent system alongside the trains, Siemens Mobility Head of Strategy and Business Development, Rail Infrastructure, Gaya Venkataraman explained that the digitalization of signalling, electrification and traffic management solutions will also deliver significant improvements in train performance. “Practically of course some field elements such as point machines will always be physical assets,” she noted “but in the future there will be no signals there will just be these assets in the field whilst the logic is more and more centralised and hardware independent; you can really decouple the field elements from the interlocking computer.” This is the basis for Siemens DS3 or ‘Distributed Smart Safe System’, a cloud-based platform which sees a move away from the big racks of proprietary servers commonly associated with interlockings and Radio Block Centers (RBCs) to emulators taking up just a couple of racks and running on commercially available hardware with the latest CPU technology or even on the cloud. “It is also important”, she noted, “ to talk about the migration capabilities – existing safety applications can be easily migrated to the new DS3 platform without extensive new investments. This paves the way for a cost-efficient country-wide digitalization of infrastructure”.

As with the supply of data from the trains the flow of information from assets will be key to ensuring equipment failures are eliminated or reduced as much as possible, a point machine reporting that it is using excessive current or generating unexpected heat when operating can not only trigger action by engineers but may give the signalling system clarity over whether it can continue to be used for a number of hours or if it should be taken out of use, with train movements planned with this in mind. Venkataraman commented “The more you connect assets, and enhance information flow between systems, the more insights you draw from them, and you start talking about predictive maintenance at an asset level as well as optimizing the performance of the system. Using big data and analytics you can also learn from the behaviour of the point machine or a door or the entire system, so you can possibly increase the lifecycle of your assets, meaning you don’t have to replace them when it’s not necessary but can also predict failures ahead of time and increase reliability and availability of the system.”

Looking more towards the integration of trains and infrastructure which can deliver Automatic Train Operation there are clear performance gains that can be achieved by moving towards a digital solution and harnessing The Cloud to take control, but Venkataraman accepted that for main line operation, as opposed to metro systems where the absence of a driver has become the norm, passengers may still expect to see someone in a cab for some time, even if their function is limited to primarily obstruction detection and initiating ATO operations “We could technically talk about going from a driver sitting in the cab to no driver, but already we’re going to see significant benefits with a highly automated driving (GoA2) system. Then it’s also about evolving from where we are today to a point in the future when there will surely be driverless systems, but perhaps not yet.” The more significant point is that if this is to happen all operators, currently using a range of different signalling systems must to work together on the “huge effort” to develop a standard specification that will allow a driverless train to move from country to country, Venkataraman added “You need a lot of players to play together and that is why the replacement of the multitude of incompatible legacy train control systems with ETCS is long overdue, because now ETCS is taking care of the standardisation of different train control systems.”

With an eye on energy efficiency, it is also clear that ATO can deliver significant benefits. Venkataraman noted “Automating the acceleration and braking control can save up to 37% of energy consumption.” Of course there are those who suggest that driver ‘intuition’, making decisions because of how a train ‘feels’ can never be replaced but Venkataraman challenged that assumption “One should also be aware that now we are making the specialist knowledge the single point of failure; what if this person retires? The industry is already facing skill shortage. That’s also a reason for automation and we need to think carefully how do we teach computers that sort of intelligence?”

For the industry the next steps are for it to understand the process of moving to a digital system and to be reassured that moving to ETCS and ATO can be done progressively as a system is overlaid onto existing legacy systems. Migration is a step which causes concern and Venkataraman was keen to offer assurance that solutions are in place “There are two different aspects; how can we reduce the complexity of the wayside architecture and centralise it and how do we make train operation more intelligent and automated. The DS3 platform is designed in such a way that you could now take the vital application from whichever generation of proprietary hardware you’re talking about and put it on this platform without a lot of customization. This enables us to move towards hardware independence and cloud-readiness, but also it can be done seamlessly without stopping the whole network.”

At the same time control of the field elements such as point motors can be migrated to fibre optic cables which result in cost-efficient operations of rail networks. Meanwhile location of vital software in The Cloud, decreasing reliance on a physical data centre, not only delivers high levels of safety and integrity but enhanced protection from a natural disaster to a local attack .

This is the solution Siemens Mobility can offer, but of course the biggest challenge is to take the industry into a new way of thinking and operating that digitalisation offers.

The challenge for Siemens has not just been about the move to The Cloud but ensuring that customers can trust something that they can’t physically see to work reliably and without latency when it comes to ‘mission critical’ decisions. They also need to be confident that it is safe and secure; “As much as we talk about digitalization we need to remember that cyber security is the other side of the same coin.” Venkataraman explained, noting that security solutions need to evolve at the same pace as new digital technology is rolled out in order to gain the confidence and trust of customers. This will place demands on Cloud providers as well as the supply chain for digital services.

Venkataraman concluded “It’s always this iceberg model; technology is only at the tip of it. Then you have processes that need to align with the technology transformation and then the mindset; people also have to align with this transformation. That’s going to be a long term process.”

Holistic Rail Cybersecurity

As the speakers noted, Cyber Security is the issue that goes alongside more digitalization, Siemens Mobility Product and Solution Security Officer, Christian Paulsen explained “By harvesting the fruits of digitalization we see a lot of opportunities for improvement in the rail experience but there are also safety and security risk aspects. Whatever we do we have to do it responsibly, and the needs are coming in different shapes; We need to ensure, that segmented networks are properly protected or we might be collecting data that is more personally identifiable and then suddenly data privacy plays a role. So you need to be able to map the security needs of each and every subsystem that a railway is made out of, and apply security technologies wisely so that the system can still operate at a at a defined risk level.”

Ensuring data is secure and systems cannot be hacked must be taken seriously, the possibility that someone could take control of a signalling centre or a train running under ATO is unthinkable, and this needs to be addressed continuously, as Paulsen explained “It might be that certain technologies become available to certain hackers, and a threat that you’ve seen in a moderate way is suddenly growing. The effect is that you can’t say ‘this is secure’ once and forever. At a certain point in time you have to revisit your assessment and check whether it’s still the case.” A balance needs to be found as well; conflicts may arise between those who need to share data and those who feel that because of cyber security this should not be the case. The list of considerations is long, there are financial implications and there are unknown risks; what if someone hacks a system just to prove it is vulnerable and accidentally takes over control? As with many areas of security this might mean bringing in someone who Paulsen described as “Sees things through the eye of an attacker” and who will specifically look for security weaknesses. The challenge grows as the size of a system increases and guaranteeing that it is secure becomes more difficult.

The good news is that there are solutions available; data can be sent securely via relatively open transmission networks, “There are technologies and we have a patented data capture unit that allows you to communicate securely out of air gapped networks over TCP IP” Paulsen noted. Using the correct data transmission options and carefully differentiating between critical and non-critical information should make any attempts to hack systems very difficult, “The encryption technology to a new standard is available to the IT market” Paulsen explained.”

At the end of the day the choice will be about balancing the cost and the risk of further digitalisation against the vast array of benefits it can bring, as Paulsen concluded. There may be some costs for security features implemented in projects upfront, the operational side however has to be considered as well “We know that some railways already have cyber defence centres up and running. Their interaction with operations in case of cyber incidents still goes through some learning curve.

I keep repeating the six elements; people, processes and products – you need the right people with the right skill sets and the security awareness from the top management and you need the right products; you have to have the right security technology. Then you have to integrate this, you have to know what level of security you want to deliver for your customer, the operator, for their operation. It needs to be interoperable and usable across the entire supply chain and finally, last but not least, there is the timeline; you have to continue to do this over many years for a project and decades for operations.”

Going forward, Siemens Mobility will continue to pioneer the digitalization of public transport. However, to fully tap the potential offered by digital transformation, the data and systems that keep our society and business safe need to be protected. The ability to provide the necessary products and services to do that will allow both operators and passengers to fully benefit from the modern technologies being developed today.