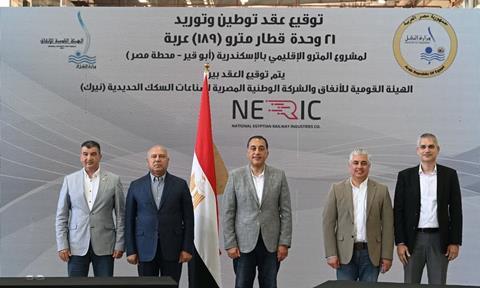

EGYPT: The National Authority for Tunnels has signed a €275m contract with local manufacturer National Egyptian Railway Industries Co for the supply of 21 nine-car metro trainsets for Alexandria.

The deal was announced during a visit by Prime Minister Mostafa Madbouly to the NERIC plant in East Port Said on May 11. The contract will run for three years and two months, followed by 10 years of maintenance including the supply of spare parts and one major vehicle overhaul.

The Prime Minister emphasised that the Ministry of Transport was planning ’to implement a number of sustainable mass transport projects in the Alexandria Governorate, as it is the second most populous’.

The 21·7 km first stage of the Alexandria metro is being developed by a consortium of Orascom Construction and Colas Rail under a €1·3bn contract awarded in September 2023. This covers the conversion to metro standards of an existing suburban railway which runs from Misr station in the city centre to Abu Qir in the northeast.

NERIC plant to open in July

During the Prime MInister’s visit, NERIC Managing Director Ahmed El-Mofty confirmed that the first phase of the factory would be ready to start production by July.

Established in 2020, NERIC is a public-private joint venture between the Egyptian Sovereign Fund, Suez Canal Economic Zone Authority, Samcrete Investments, Orascom Construction, Hassan Allam Holding, Connect Professional Services and East Port Said Development Co.

The facility is being developed in partnership with Hyundai Rotem, which signed partnership agreements with NERIC in 2022 covering localised production. The 40 eight-car trainsets that Hyundai Rotem is supplying for Cairo metro lines 2 and 3 are also to be assembled at the plant.

The plant will eventually occupy an area of approximately 30 Ha, and is predicted to generate 5 000 jobs when fully operational.

The facility is being constructed in three phases. The first two stages are intended to accommodate the production of electric locomotives and multiple-units, urban rail vehicles, and freight wagons, with the company’s product portfolio targeting the wider African market.

Completion of the third stage of the plant would add facilities for the maintenance and repair of rolling stock.

The company is aiming achieve a 75% localisation rate for production within three years of opening.