- News

- In depth

- Events

- Data

- Maps

- Tenders & Jobs

Tender 42230 - Supply of Forklifts and Reachstacker for ISR’s Cargo Division

Tender 42230 - Supply of Forklifts and Reachstacker for ISR’s Cargo Division Timetabling & Track Possession System (“Tender”)

Timetabling & Track Possession System (“Tender”) Request for Information (RFI) Concerning “Flatcars for Transporting Refrigerated Containers”

Request for Information (RFI) Concerning “Flatcars for Transporting Refrigerated Containers” Pre-Qualification Process 589/2025 INVITATION TO PARTICIPATE IN A PARTICPANTS’ CONFERENCE

Pre-Qualification Process 589/2025 INVITATION TO PARTICIPATE IN A PARTICPANTS’ CONFERENCE

- Sponsored content

- Insights

Close menu

- Home

-

News

- Back to parent navigation item

- News

- Traction and rolling stock

- Passenger

- High speed

- Freight

- Infrastructure

- Policy

- Technology

- Ticketing

- Business

- Research, training and skills

- Accessibility and inclusion

- People

- Urban rail news

- Suburban and commuter rail

- Metro

- Light rail and tram

- Monorail and peoplemover

- Regions

- InnoTrans

- In depth

- Events

- Data

- Maps

- Tenders & Jobs

- Sponsored content

- Insights

The heat is on

By Railway Gazette International2009-04-30T05:00:00

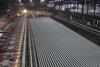

AUSTRIA: Reflecting a steady transition from standard grade rails to high-strength premium steel grades, Voestalpine has recently inaugurated a new heat treatment facility at its Leoben rail rolling mill in Austria.

Already have an account? LOG IN

To continue…

You’ve reached your limit of content for the month