INNOTRANS: On show in Berlin is a prototype four-wheeled intermodal wagon intended to improve the efficiency and competitiveness of rail freight.

Developed by the German aerospace research centre DLR with the support from national railway industry association VDB and various industrial partners, the Competitive Freight Wagon is backed by the Europe’s Rail joint undertaking through the FR8rail IV research project.

Able to carry both containers and swap bodies, the 12·7 m long vehicle weighs just 9·6 tonnes, making it at least 20% lighter than comparable conventional wagons. The CFW has also been designed for speeds of up to 140 km/h. According to the researchers, a 750 m long block train formed of CFWs could carry the equivalent of 44 lorry loads.

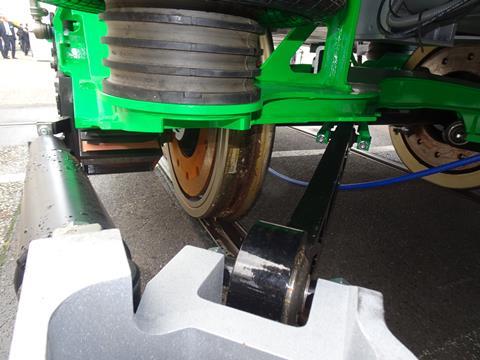

The wagon has a lightweight steel underframe carried on two single-axle trucks, with four individually controlled GMT air springs to keep it at a constant height and still fit unevenly loaded swap bodies within the permissible loading gauge. The trucks are connected to the underframe by four links that create a virtual pivot and provide a degree of radial self-steering of the wheelsets into curves. This is expected to reduce both rolling resistance and wear, while the use of disc brakes will minimise noise emissions.

The swap bodies and containers are attached to the vehicle by automated locking pins, replacing the traditional hand-operated fastenings and saving up to 5 min in the loading and unloading process. Locking the loads in place also supports operation at higher speeds, enabling freight trains to operate between passenger services on busy routes.

The brakes are electronically controlled using a Knorr Bremse EP2002 valve to reduce both braking distances and brake release times – at least when the CFWs are used in a block train.

The prototype is equipped with Dellner Type 5 digital automatic coupler carrying the data connection and a 400 V AC power feed for the onboard systems. This supports a Safe Train Integrity System which monitors and reports the status of all subsystems on each vehicle.

The motorised Type 5 DAC facilitates both the automatic coupling and uncoupling of individual wagons. Other coupler types could also be used, while intermediate vehicles in a fixed rake could have simple bar connectors. DLR envisages that the wagons would initially be operated in permanently-coupled pairs, working both point-to-point and ‘closed train loop’ services.

Aerodynamic drag is reduced to a minimum by two simple measures. Firstly, minimising the distance between the swap bodies which are typically square boxes that can otherwise create air turbulence. Two short boxes could be loaded on one wagon, while the longer coupled pairs would reduce the distance between adjacent boxes to less than 1 m. Simulation has demonstrated a significant reduction in drag, which now needs to be confirmed by practical tests. The other measure is the use of lateral skirts along both sides of the underframe, which is expected to reduce the drag by about 20%.

DLR is currently carrying out in-depth tests of the aerodynamic behaviour of containers and swap bodies, using a sensor-equipped swap body carried on the CFW wagon. This has a large number of pressure sensors mounted on all four sides and the roof to analyse air flows under different conditions and speeds.