The importance of choosing the right measuring principle for monitoring railway profiles.

Over time, the continuous interaction between railway tracks and wheels alters the shape of both the wheel and rail profiles. This leads to a negative effect on the safety, comfort and efficiency of the rail service and it is therefore important to monitor the wear and tear to better implement predictive maintenance strategies. But which method is the best, and why?

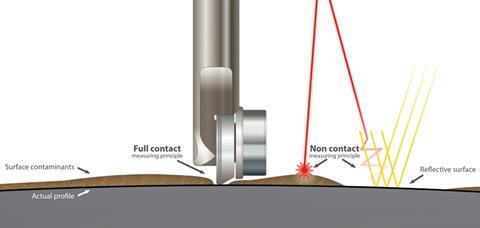

Non contact or full contact

When choosing a measuring system and method for monitoring railway profiles, there are several things that need to be taken into consideration.

The non-contact measuring principle is well suited for automated high-volume measurements when traveling at track speed. It could be the right solution when a general view of assets and a large volume of data is the priority.

However, for the highest level of accuracy and reliability, the full contact measuring principle will undoubtedly be the better option. A full contact measuring system will determine the exact state of a given profile, giving you optimum maintenance, safety and advanced profile analyses.

High volume, non-contact data is often used for easy identification of certain problem areas on the wheels or rails which must be examined more closely. To determine the exact maintenance need of the problem area, reliable and high-accuracy profile measurements are of the utmost importance.

This is where the full contact measuring principle is most valuable! It can be used to validate the non-contact measuring data as well as in all situations where highest accuracy and reliable profile railway data is required, for example in maintenance depots, manufacturing facilities, quality control, research, universities and more.

Full contact, full reliability

With the full contact measuring principle as provided by the market leading profile measuring tool, MiniProf, a strong magnetic measuring wheel on the device keeps constant contact to the rail track, brake or wheel profile throughout the entire measuring process. The knife-shaped measuring wheel cuts through any oil, grease and other potential surface contaminants to measure the true profile, giving the most accurate and reliable reading from 9 to 11 µm and excluding any unwanted surface layers.

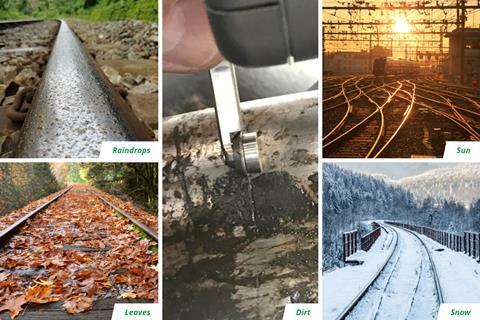

This differs from the non-contact measuring principle, that provides a scanned picture of the profile surface, but cannot distinguish between the profile or accumulated surface contaminants like dirt, oil, lubrication, leaves, snow and drops of rain etc. Therefore, there is a greater burden on the cleaning of the profile prior to it being measured. It can be a time-consuming process, but if not cleaned adequately, the non-contact measured result is likely to misrepresent the true profile, potential leading to false or incorrect profile analysis.

Working environment

The rail industry works in all environments, and so does the full contact measuring principle. It is not compromised by environmental factors and therefore can work anytime you need it to, no matter if the sun is shining or it is icy cold.

This is a sharp contract to the non-contact measuring principle that can be limited by reflections from the sun, newly turned wheels, grinded rails, bright brakes, other shiny objects or dew or snow on the rails. Measuring using a non-contact system in less than optimal conditions can result in misrepresentative measurements which will either have to be repeated or postponed, costing time and money. When using the non-contact measuring principle, the working environment has to be considered carefully.

The MiniProf systems

The small full contact MiniProf units are made from lightweight, ultra-strong titanium making them easy to transport and use. They are fast to use, offers instant results and the absolute best accuracy available on the world market. Used globally by thousands of customers, they are considered by many to be the “Gold Standard” of profile measurement for accurate, reliable and efficient railway profile data.

The accompanying software, Envision, contains numerous options for basic to advanced analysis, and can be set up and used quickly and easily. It is highly customizable to customer’s requirements both when performing measurements and with post measurement analysis. Some included features are; vast evaluation module, guided measurement schemes to facilitate the measuring process, trend analysis of wear for predictive maintenance, volume data calculations and numerous other additional analyzing possibilities including equivalent conicity.

The full contact and high accuracy MiniProf units combined with the powerful Envision software is an accurate, reliable and perfect system for minimizing risk while maximizing efficiency and optimizing budgets.

More information available at https://greenwood.dk/