Products

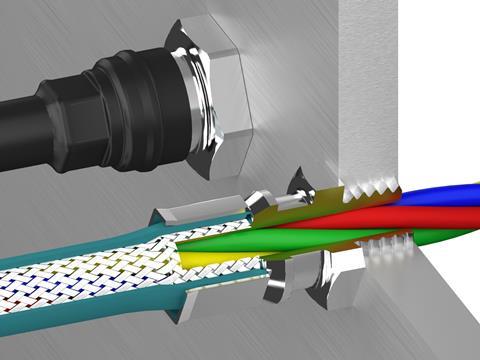

- 360° Cable Shield grounding for best possible EMI/RFI shielding

- Maximum strain relief and torque resistance

- Easy, safe and reliable processing, even in field applications

D-Sub standard solutions for CAN and Profibus as well as MVB/WTB (railway technology) and individual configurations or other BUS types on request.

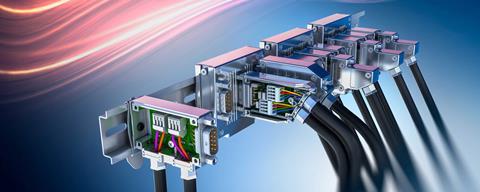

EMC-compliant thanks to full metal housing and 360° cable shield connection with Inotec crimp flange technology.

The appropriate housing for all applications: MSBS series for maximum packing density or M30 for DIN rail mounting or couplings.

Specialized in critical Railway applications like ETCS systems, Inotec has developed a robust and EMC-compliant interface for Type F connections. The system uses Inotec crimp flange technology with 360° shield grounding for maximum EMI/RFI protection and it allows a quick and reliable fixation and grounding of connectors on 19” racks and backplanes.

- Safe

- Up to 70 coding versions offer protection against unintentional or abusive mating of connectors

- Full metal coding elements improve grounding contact for optimal EMC

- Robust

- Coding elements are either riveted to the connector shell or screwed on the device

- High-end and precise full metal components

- Reliable

- Accurate alignment with special positioning device

- Inserting the coding pins process-reliable thanks to a preset tool

- Compact hand-tool for Inotec crimp flange technology with unique „pivoting upper die“.

- Easy single-hand operation.

- Insertion of ferrule sizes up to 20 mm.

- Allows processing with a maximum of reliability and repeatability, no presetting and calibration required.

- To be used according to cable-specific Inotec crimp data definition.

- Accessories: CB202-xxx(T) hexagon crimp die-set.

- Pre-calibrated (no adjustment required).

- Optional T-indent for improved torque resistance in upper die (according to cable-specific crimp data definition).

- Easy exchange,

- Min. size AF 3,5 mm (across flats)

- Max. size AF 20,0 mm

- Standard sizes on stock

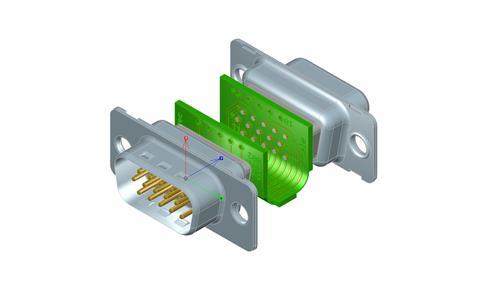

Inotec electronics GmbH has introduced the world’s first flex-rigid HD15 and HD26 diagnostic plugs as sub-assembly ready-for-use with Inotec M11 piggy-back hoods.

Wires of diagnostic cable can be brazed directly to the PCB or with 0,7 mm wire termination.

Flex-rigid PCB is folded after brazing and mounted to the selected M11 series hood (either piggy-back setup or as coupling adaptor).

The compact cable glands are using original Inotec Crimp flange technology with 360° cable shield grounding for maximum robustness and shielding performance. Compared to conventional screwed cable glands, the Inotec system saves up to 75% installation space.