SOUTH KOREA: Korea Railroad Research Institute has unveiled a lightweight bogie concept aimed at increasing the operating speed of high speed trains, reducing the bogie weight by 30% and improving air resistance to cut energy consumption.

According to KRRI, the rise in international energy costs has seen the unit price of domestic railway electricity increase by 72% over the past 10 years. As a result, train oeprators are increasingly looking for ways to reduce their energy consumption.

Bogies typically account for around 30% of total vehicle weight, and are also a major contributor to drag, making them a key element affecting the overall energy consumption of the train.

Streamlined design and lower weight

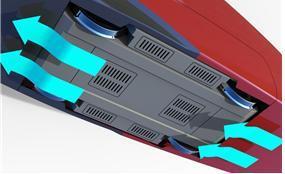

The project envisages the deployment of what KRRI describes as a ‘capsule-type bogie system’, in which the bogie frame effectively ‘boxes in’ the area below the wheelsets, helping to decrease air resistance.

Changing from outside to inside frames allows the area below the bogie to be enclosed without impacting on the performance of the suspension and drive components. This is in contrast to most current bogie types which the frame is positioned outside and above the wheelsets, leaving unshielded components which contribute to higher drag forces.

KRRI estimates that the inside framed bogie will be 29·5% lighter than current designs.

Motors and brakes modified

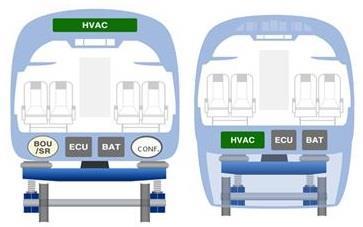

As part of the weight reduction drive, the new bogie would be powered by a permanent magnet synchronous motor which is small enough to be fitted between the inside frames. The power transmission has also been redesigned with smaller components and an improved connection between the traction motor and gearbox.

The size of the braking system has been reduced by adopting electro-mechanical control, rather than the normal pneumatic actuation. Because the bogie shielding reduces the ventilation by natural airflow, a brake cooling system has been developed as part of the concept. Analyses suggest there will be no issues in terms of increased heat generation.

The project also included the development of a more streamlined train nose with an optimised profile.

KRRI says that the new design structure has been verified through analyses and safety simulations, and prove to be stable at speeds exceeding 550 km/h, even under worn wheel conditions. The bogies will be meeting European standards EN 14363 and EN 12299 for dynamic performance and ride comfort.