JAPAN: A low-cost enhancement to improve the efficiency of three-phase traction motors has been developed by Toshiba Corp.

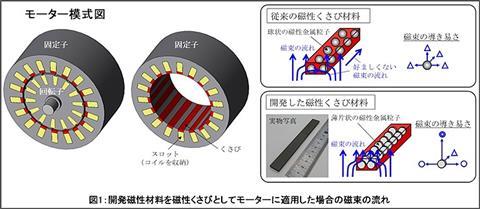

Unveiled at the 57th Annual Meeting of the Electronic Materials Technology Association of Japan on December 4, the technique involves the use of magnetic wedges to secure the coils in the stator of an asynchronous induction motor. Toshiba estimates that this could improve motor efficiency by around 0·9%, to a figure comparable with a synchronous permanent-magnet motor.

In an induction motor, an induced current is generated in the rotor by varying the electromagnetic force in the stator coils, and the rotating magnetic field causes the rotor to turn.

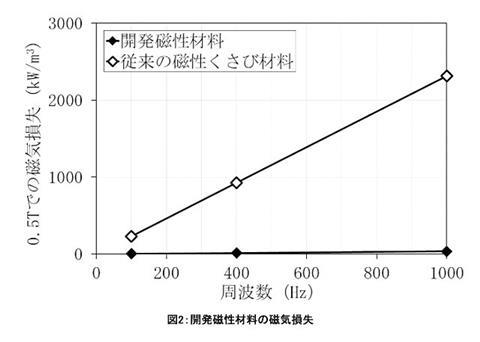

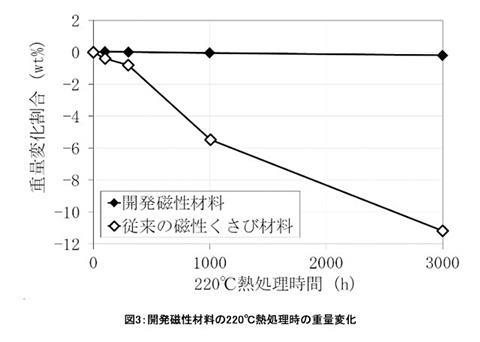

The wedges used to secure the coils in slots around the stator are normally made from a non-magnetic material. According to Toshiba, exchanging these for magnetic wedges helps to direct the induced flux, enhancing the energy conversion. The company has developed a material offering ultra-low magnetic loss and excellent flux controllability along with high heat resistance. This incorporates ‘flaky’ metal particles, and has variable magnetic properties that depend on direction. A heat-resistant binder minimises any loss of magnetism, even when exposed to temperatures up to 220ºC for long periods.

Making the coil wedges from this material guides the magnetic flux in the motor in a specific direction (Fig 1), helping to reduce energy losses. According the manufacturer, this is a low-cost improvement which requires very little maintenance. The technique is said to be particularly effective for medium to large induction motors, and can be implemented without changing the design of the motor.

Toshiba estimates global power consumption to be around 22 trillion kWh per year, of which 45% is used to drive electric motors. It suggests that a 0·9% improvement in efficiency for all motors would result in an annual saving equivalent to 10 GW, or the output of 10 power stations.