3M Materials and Adhesives Science have transformed exteriors and interiors of High-Speed Trains (HST) through solving challenges of speed, energy efficiency and stability, allowing manufacturers and operators to focus on improving passenger experience and comfort in new designs. With a complete portfolio of innovative adhesives and tapes, and years of application engineering experience in the rail market, 3M is the right partner to help you solve your design and assembly challenges in rail car design and manufacturing.

A transformation journey through science

Traditional long-distance passenger coaches are robust vehicles that meet the objectives of transporting passengers in a reasonable time, but time now has become one of the most valuable concepts for modern societies. Many regions have seen their trains and infrastructure transformed into high-speed networks, converting distance into a balance of time, efficiency and passenger comfort. Science and innovation have enabled this transformation in many areas such as motors, bogies, tracks, car bodies, fairings, windows, and interior trimmings.

To compete with other modes of transportation, high-speed trains need to adapt their design for optimal payload, energy efficiency and comfort criteria: double decks or five seats per row, aerodynamic shape, fairings and car bodies with differentiated designs, wider interior space and windows, as well as safety and passenger experience. These all contribute to providing a safe and comfortable journey in a competitive landscape where operators rival each other to get passenger preference.

Polymers science has allowed advanced features in high-speed trains such as improved stability, weight reduction, composite manufacturing and integration, multi-material assemblies, vibration damping, thermal and noise insulation and many other features such as accessibility. Today, we cannot imagine an aerodynamic nose or passenger car windows with visible screws, welding or visible metal frames; polymers are not only key for reducing air friction but also for getting the most forefront interior and exterior designs.

Comfort and customization enabled by polymeric materials and adhesives innovation

When it comes to providing superior comfort, rail operators and manufacturers of high-speed trains must apply innovative methods such as ‘design thinking’ and ‘technologies watch’ to meet passenger needs and expectations. With a passenger-centric focus and purpose, operators and manufacturers customise their train designs integrating quiet cars and cafeteria cars, as well as providing convenient services such as connectivity, privacy, thermal and acoustic comfort. The use of advanced assembly methods such as adhesive bonding plays a key role here, enabling customised and flexible designs and delivering the required performance. Adhesives and tapes provide reliable solutions to many of the challenges around comfort, durability and safety.

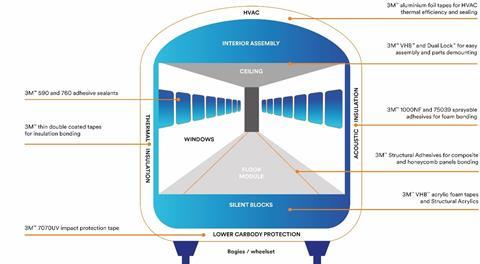

3M adhesives and tapes solutions and 3M rail experts help engineers to develop advanced high-speed train projects. From exterior parts bonding and protection to interior assembly and insulation, the 3M adhesives and tapes portfolio includes the most advanced technologies in the market to meet these requirements. The cross section shown in fig 1 provides examples of the possible application areas for 3M adhesives and tapes.

The advantage of toughness and flexibility of acrylic adhesives

Acrylic adhesives and tapes are one of the leading bonding technologies for multi-material bonding when toughness, impact and fatigue resistance, flexibility and quick bond are required.

When two high-speed trains pass each other at 300 km/h, whether in a tunnel or on an open section of track, all parts suffer deformation from air pressure and suction. Safety and passenger comfort are compromised by forces that require a strong and tough assembly design. Acrylic adhesives and acrylic foam tapes play a significant role in stress absorption and dissipation. New generation of 3M structural acrylic adhesives such as DP8407NS provide a long-term resistance to stress cycles when bonding inserts, metal and composite parts, with a reinforced formulation having superior resilience and tenacity.

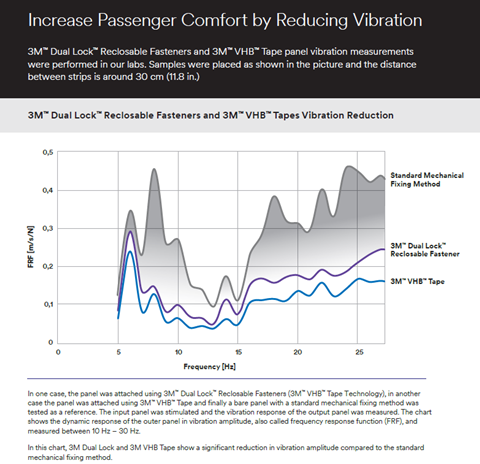

3M VHB acrylic foam tapes and 3M Dual Lock recloseable fasteners contribute to making durable interior assemblies of wall panels, window frame covers and ceilings, with improved aesthetics and vibration dampening compared to other joining methods. In the floor module, 3M VHB tapes are used to bond floor covers including carpets to the floorboard, providing superior stepping comfort as well as a strong bond when operators and manufacturers expect more than 10 years of durability - especially in high transit areas. They also allow easy replacement of damaged floor covers compared to other floor cover assembly methods. Below the floorboard line, 3M VHB acrylic foam tapes are used to bond the floor panel to the structure, providing a consistent thickness and an elastic, stress-dissipating bond that contributes to reducing floor vibrations with a convenient self-adhesive high performant acrylic foam polymer.

Other interior components such as toilet modules, luggage compartments, partitions and catering equipment use 3M VHB tapes for bonding metal, composites, plastics, and clear panels to provide a quieter, elastic and lighter assembly.

The benefits of durability, superior mechanical, and flexural strength of epoxy adhesives

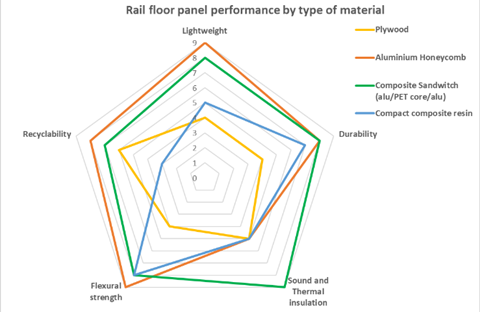

Epoxy adhesives offer chemical, corrosion and moisture resistance. They are also one of the strongest adhesive families when mechanical and flexural stress resistance is required for structural panels such as floor panels or doors. High-speed train floorboards and doors can be stressed by constant vibration, twisting and bouncing. 3M epoxy adhesive SW7240B/A FR is an example of advanced epoxy technology with more than 20 years of successful application in the rail industry. This reinforced epoxy formulation and its high modulus make dissimilar material assemblies durable for the life of a rail carriage, designed to maintain the resistance of structural panels through years of hard use.

2K epoxy adhesives have demonstrated best-in-class performance in floor panels manufacturing, providing the highest flexural resistance, thinner panel designs and long-term resistance. Honeycomb and sandwich composite floor panels bonded with 3M SW7240B/A FR epoxy deliver significant weight reduction advantages compared to plywood and differentiated benefits such as extended durability, recyclability and insulation performance.

Click here to watch our on-demand webinar on interior panel bonding solutions

Lightweighting is at the core of getting the best balance between energy efficiency and passenger payload. Strategies for high-speed trains focus on specific designs, but also depend strongly on the use of lighter materials. These materials, together with the appropriate adhesive selection, will have to maintain the structural integrity of the vehicle and deliver the reduction of weight expected for the intended payload. At the same time, they will have to meet passenger comfort objectives and safety requirements. The 3M adhesives portfolio provides the best in market solutions to reach the objectives of lightweighting, safety and durability, and are also able to target specific vibration frequencies to provide an efficient damping effect for lighter panels.

Click here to download the full 3M Dual Lock design guide

Contact 3M Experts for solutions to your design challenges

To maximise the benefits of high-speed trains for passengers and overcome the challenges of weight reduction, space increase and noise/vibration management, designers and engineers can choose from a wide range of 3M adhesive technologies that provide advantages over traditional attachment methods. Designers and engineers can count on 3M experts with years of experience and a portfolio with proven performance in the rail market to help them make the best choice for their high-speed train projects.

For more information on addressing assembly and design challenges in rail market, please visit 3M Rail Industry Solutions website.

To request contact from a 3M rail expert, please connect with us.