JAPAN: Central Japan Railway has developed an automated overhead line inspection system that can be fitted to series-built trains used on the Tokaido Shinkansen. Able to check the position of wires and the condition of fittings while trains are travelling at up to 300 km/h, the roof-mounted equipment will be used to complement the inspections carried out by the Dr Yellow dedicated infrastructure inspection trainset.

JR Central has developed the automated equipment in anticipation of future labour shortages as it reduces the need for foot patrols to check for defects in the overhead line infrastructure. It will also be used to step up the frequency of inspections.

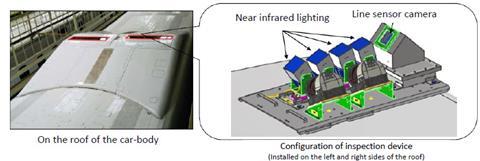

The equipment uses a combination of near-infrared lighting, laser range scanners and line sensor cameras to check the position of overhead wires and the condition of metallic components in 3D. Artificial intelligence then assesses the data for defects, damage or deformation. Using mm-wave radio that is due to be introduced in 2027, the data will be transmitted to maintenance centres, helping to ensure timely intervention by maintenance teams.

The train-mounted equipment will eliminate the need for maintenance staff to use instruments to measure the height of overhead wires and the distance between them at locations where they intersect. Until now these measurements were made using visual checks, with much of the work done at night when no commercial services were operating.