SWEDEN: Alstom is investigating how origami-inspired manufacturing techniques from Stockholm-based design and technology company Stilfold could be used to make rolling stock production more sustainable.

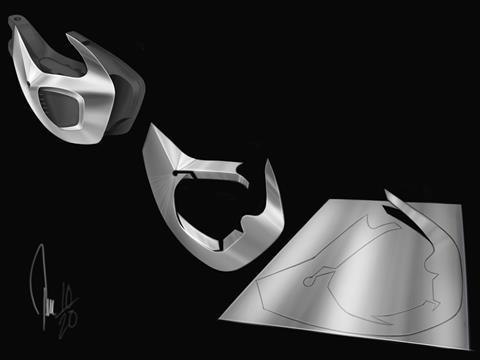

Stilfold’s patented ‘industrial origami’ inspired by the Japanese art of paper folding involves the use of robotic arms to fold flat sheet metal over curves to form strong structures with minimal component parts. This removes the need for cutting, welding and joining, and thus reduces material waste, energy consumption and production time.

Stilfold’s Stilware software defines the optimum geometries along complex and curved lines. Its Stiltool transforms CAD data into CAM instructions for automated robotic folding and forming, with its Stilworks production cell allowing manufacturing by any fully equipped metal workshop.

Stilfold will work with Alstom to review existing rolling stock manufacturing to identify areas where the greatest impact could be achieved.

Stilfold has previously created a lightweight electric motorcycle made from recycled steel, and it is working with Polestar to build a climate-neutral car and with Kookiejar to produce ‘vertiports’ for urban drone deliveries.

‘Our aim is to power sustainable manufacturing practices across every industry’, said CEO and co-founder Jonas Nyvang on September 11. ’Mobility is a key focus for us, which is why we’re so excited to be moving into the rail sector through this collaboration with Alstom. Rail travel has always been one of the most environmentally friendly modes of transport, but it could be made even greener by optimising train construction for sustainability. We can’t wait to explore what this could look like in practice.’